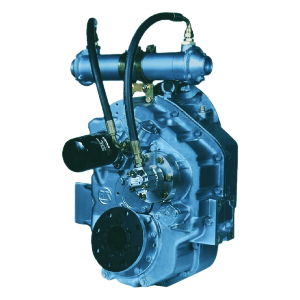

ZF Hurth 280-1 Marine Transmission Maintenance:

Ensure Propulsion System Reliability: Expert Tips for ZF Marine Transmissions Maintenance

Ensuring the reliability of your vessel’s propulsion system is crucial for smooth sailing and peace of mind on the water. At the heart of this system are the ZF Marine Transmissions, which require regular and informed maintenance to perform optimally. By focusing on key practices such as marine transmission maintenance, fluid replacement, seal inspection, and alignment checks, you can significantly extend the lifespan and efficiency of your transmission. In this post, we will provide expert tips and insights into these essential boat maintenance tasks, empowering you to keep your marine adventures trouble-free and enjoyable. Whether you’re a boat owner, marine mechanic, or maritime enthusiast, understanding these practices is the first step towards propulsion system reliability and excellence.

Essential Maintenance Practices

Regular Fluid Replacement

Regular fluid replacement is a critical aspect of marine transmission maintenance. Fluids in your ZF Marine Transmissions are essential for lubrication, cooling, and the elimination of impurities that can damage internal components. Over time, these fluids degrade and lose effectiveness, risking the transmission’s performance and longevity. Therefore, adhering to a consistent schedule for fluid checks and changes is crucial. Typically, the manufacturer’s guidelines will specify the recommended intervals for fluid replacement. However, factors such as usage frequency and operating conditions may necessitate more frequent changes. When replacing fluids, always use the recommended type and ensure the correct quantity is used. This simple yet effective maintenance step enhances propulsion system reliability, reduces wear and tear, and helps prevent costly repairs. Regular attention to fluid levels and condition will keep your ZF Marine Transmissions in peak operating condition, ensuring smooth sailing on all your maritime adventures.

Thorough Seal Inspection

Regular seal inspection is fundamental in maintaining propulsion system reliability. Seals and gaskets in ZF Marine Transmissions prevent fluid leaks and maintain optimal pressure within the system. Over time, these seals can wear down or become damaged, leading to leaks that compromise performance and may cause significant damage if left unchecked. Conducting thorough inspections allows you to identify and address potential seal issues early. During inspections, check for signs of wear, such as cracks or brittleness. Pay close attention to areas where the seals meet other components, as these are often stress points. Replacing worn or damaged seals promptly can prevent costly repairs and downtime. Additionally, ensuring seals are properly installed and seated helps maintain the transmission’s integrity. By prioritizing seal inspections in your boat maintenance routine, you can enhance the longevity and efficacy of your ZF Marine Transmissions, ensuring a reliable and enjoyable boating experience.

Accurate Alignment Checks

Accurate alignment checks are indispensable for ensuring propulsion system reliability. In ZF Marine Transmissions, misalignment between the engine and the transmission can lead to excessive vibration, increased wear, and even severe damage over time. To prevent these issues, regular alignment checks should be part of your marine transmission maintenance routine. Misalignment can arise from routine use, changes in load, or impacts during operation. Identifying misalignment early can prevent these problems from escalating. During checks, ensure that the alignment is within the manufacturer’s specified tolerances. Specialized tools and gauges can help detect even minor deviations. If misalignment is found, adjustments should be made promptly to prevent further complications. Professional assistance might be necessary for precise alignment corrections. By conducting regular alignment checks, you protect your investment in ZF Marine Transmissions, enhancing both performance and lifespan. This proactive step ensures your vessel remains ready for reliable and smooth operation on the water.

ZF Marine Transmission Maintenance, our Trained Technicians at Santa Barbara Marine Diesel Mechanic, serving, Channel Islands Marina, Ventura Harbor & Santa Barbara Harbor, Provide Expert service on all ZF Marine Transmissions. ZF Marine provides a complete line of high-performance lightweight gearboxes with seawater proof aluminum gear housing and a wide ratio range for all types of fast vessels for engine power of up to 10,000 Kw. Large motor yachts, superyachts, offshore supply vessels, government vessels and fast ferries are typical applications for this series of marine transmissions they are characterized by an optimum power-to-weight ratio, capable of withstanding high loads under extreme operating conditions. ZF-Oil-Recommendation-Marine-Transmissions-2020.pdf

ZF Marine Transmission 302IV:

- Compact yet durable design.

- The design is virtually leak-free and simple to maintain.

- Trolling valves are available.

- Available for twin engine installations

- Suitable for full power use in forward or reverse

- Several ratios available

- Accepted by all major Classification Societies

- Live power-takeoffs can be installed at any time.

- ZF transmissions come with heavy-duty mounting brackets and complete oil cooler systems.

- Transmissions equipped with electric shift valves have a feature that allows engagement of the valve with the turn of a screw if the electrical power source fails.

ZF Marine Transmission 302IV:

ZF-Oil-Recommendation-Marine-Transmissions-2020.pdf

Marine > Applications & Products – ZF

Small-Medium Transmission Range – ZF

Blog – 805 Marine Diesel Mechanic (sbmarinemechanic.com)

3 Responses